DTF Printing

High-quality and durable printing for all types of fabrics

DTF printing (Direct to Film) is an innovative and versatile textile customization technology that allows high-quality designs to be transferred onto a wide range of textile products. Unlike other methods such as sublimation or direct printing, DTF uses a unique process in which the image is printed onto a special film, polyamide powder is applied, and then it is cured in an oven before transferring the design onto the fabric with a heat press. This method stands out for offering vibrant colors, high durability, and the ability to work with all types of fabrics, including dark and synthetic ones.

Advantages of DTF printing

- Flexibility: compatible with all types of fabrics, including cotton, polyester, and blends.

- Versatility: DTF can be applied to both dark and light garments.

- Print quality: high-resolution transfers rich in detail.

- Durability: DTF prints offer excellent wash resistance, even with strong detergents.

- Cost: although the initial investment may be higher, the cost per print is very low and offers high profitability in the short term.

Why choose InkOne?

At InkOne, we combine cutting-edge technology with a strong focus on quality and customer satisfaction. Our equipment and consumables have been selected and developed by experts to optimize every step of the DTF process, ensuring consistent and professional results from printing to transfer. In addition to our complete range of DTF printing equipment and consumables, at InkOne we offer:

- Specialized technical support

- Spare parts guaranteed for all our machines

- Warranty on all our products

- Large inventory and fast delivery

InkOne DTF Printers

Designed for all types of clients, from entrepreneurs to industrial production.

Discover our selection of InkOne DTF printers, designed to deliver high-definition prints for all types of customers. From compact models like the InkOne DS1 DTF printer to industrial-grade options, we have the perfect solution for your customization business.

InkOne DTF Ovens and Applicators

Advanced technology to ensure high precision in the curing and powder application process

Drying ovens for sheets: compact and easy to use, perfect for small-scale production.

Automatic ovens/applicators: ideal for large-scale production, automating both powder application and curing in a single machine.

DTF Accessories and Consumables

Products designed to ensure superior performance and precise, long-lasting printing

We offer a selection of high-quality products, from specialized papers and advanced inks to smoke purifiers, cleaners, and polyamide powders.

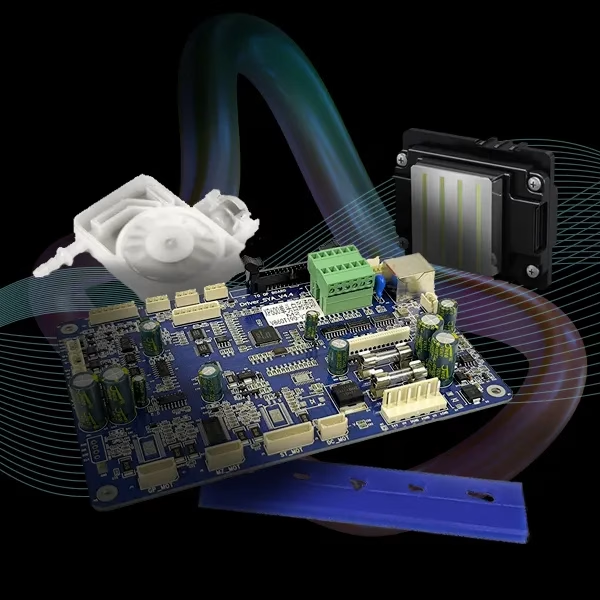

DTF spare parts

We offer a full range of high-quality spare parts

Special printheads for DTF inks.

Products designed to maximize the performance and lifespan of DTF printing equipment.

Quick-installation parts to minimize downtime and simplify maintenance.

Filters, ink tanks, removers, capping, encoder, tubes, plates, and more.

Frequent questions

DTF printing (Direct to Film) is a textile personalisation technique that consists of printing a design onto a DTF film and then transferring it onto the fabric using heat and pressure. This process delivers high-quality finishes, excellent flexibility on the fabric, vibrant colours and outstanding durability.

DTF printing is compatible with a wide range of fabrics, including cotton, polyester, blends, technical textiles and both light and dark garments. It can also be applied to complex textile surfaces where other techniques may have limitations. This versatility makes DTF an ideal solution for businesses working with different types of garments and looking for a single system to cover multiple personalisation needs.

The main advantages of DTF printing include its versatility across fabrics, the ability to produce complex and multicolour designs, and the absence of limitations related to garment colour. In addition, it offers an excellent balance between quality and cost per print, does not require large minimum runs and helps optimise production times. These features make it a highly competitive alternative to sublimation, heat transfer vinyl and traditional screen printing.

The main difference between DTF printing and sublimation lies in the types of materials they can be applied to. While sublimation is limited to white or light-coloured polyester fabrics, DTF allows customisation on virtually any textile, regardless of colour. In addition, DTF offers greater flexibility in terms of garment types and finishes, making it a more versatile option for many businesses.

The choice between DTF printing and screen printing depends on the type of production. Screen printing is more suitable for large runs with simple, repetitive designs, while DTF is more cost-effective and flexible for customisation, complex artwork and short or medium production runs. For businesses working on demand or handling multiple designs, DTF printing is often the most efficient solution.