Automation and Efficiency

The DTF Dryer and Shaker InkOne SM3 (35 cm) optimizes workflow with automatic powder application and curing, allowing continuous and uninterrupted production.

Precise Digital Control

Easily adjust the temperature, powder application speed, and agitation, ensuring flawless curing with all types of films, inks, and powder.

Integrated Purifier

Ensures a clean and safe work environment by eliminating gases and particles with HEPA and carbon filters.

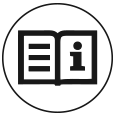

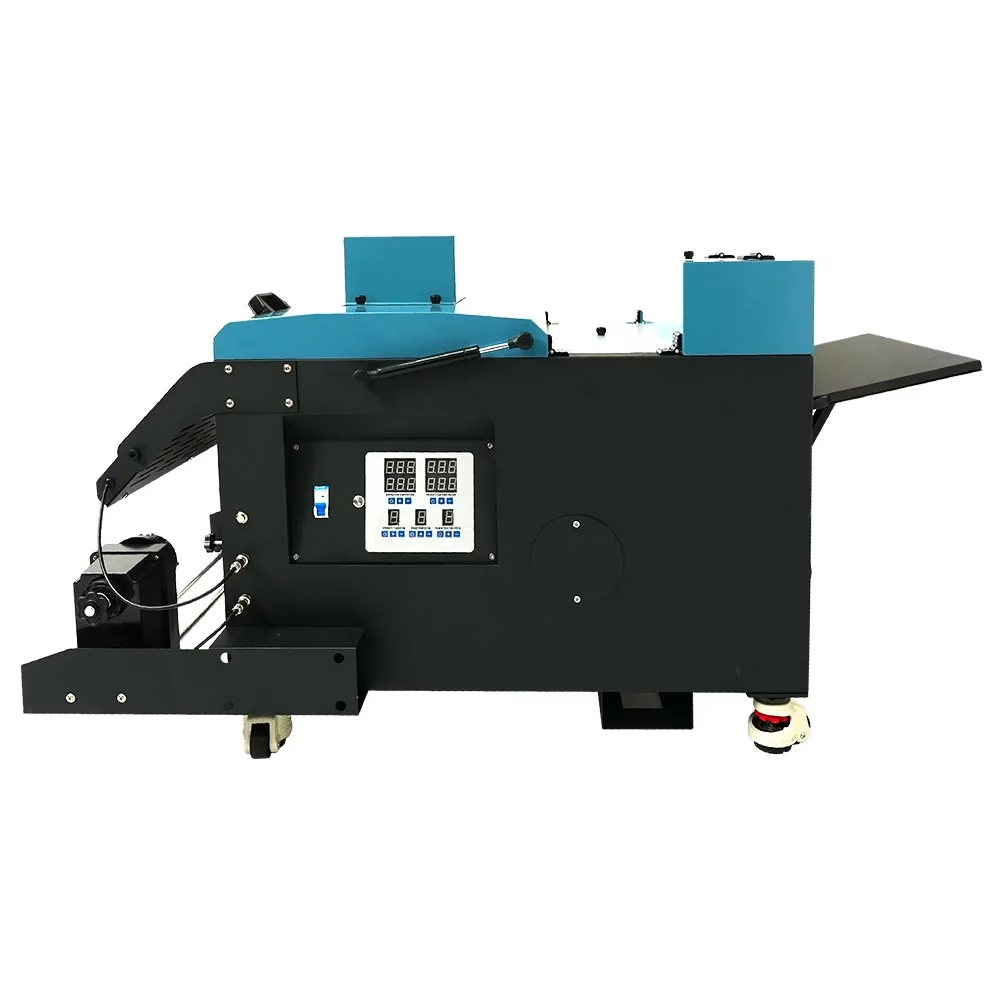

DTF Dryer and Shaker InkOne SM3

- Supports film rolls up to 35 cm wide, allowing a large production capacity.

- Its precise digital control allows for easy adjustment of oven temperature, powder application amount, and agitation speed, ensuring uniform curing.

- It is easy to operate, with an intuitive design that allows anyone to handle it with minimal training.

- The top compartment for polyamide powder allows for safe powder addition, optimizing the application and preventing spills.

- The removable drawer for excess powder allows for recycling of the surplus, reducing waste and keeping the workspace tidy.

- An automatic film collection system facilitates handling and storage by automatically rolling the film after curing.

- The HEPA and carbon filters guarantee a safe working environment by eliminating harmful gases and particles.

- The disposable filters are easy to handle, simply replace them when saturated.

Technical Specifications | DTF Dryer and Shaker InkOne SM3 (35 cm) |

|---|---|

Maximum paper/film width | 35 cm |

Powder filling box | Yes |

Powder collection drawer | Yes |

Automatic powder recycling | No |

Temperature Control | Digital panel |

Voltage | 220V |

Activated Carbon Filter | Yes |

HEPA Filter | Yes |

Equipment dimensions | 62 x 87 x 95 cm (w x h x d) |

Packaging dimensions | 82 x 63 x 76 cm |

Oven weight | 45 Kg |

Packaging weight | 58 Kg |

INTRODUCTION

InkOne SM3

Dryer VS Dryer and Shaker

Feature | Dryer | Dryer and Shaker |

|---|---|---|

Main function | Image curing | Powder application, excess powder removal, image curing, and film storage |

Powder application | Manual | Automatic |

Film or paper format | Sheets | Rolls |

Powder recycling | Not available | Recycling system |

Process time | Variable, depends on operator | Film passes continuously from start to finish |

Production speed | Variable, depends on operator | Constant, automatically adjustable |

Operator safety | Operator handles hot objects | Operator does not handle hot objects |

Film/paper handling | Manual | Automatic collection system |

Continuous production capacity | Limited | High, for large volumes |

Frequently Asked Questions

The InkOne SM3 stands out for its automation, allowing simultaneous powder application and curing. Additionally, it features an integrated smoke purifier, precise digital control system, a secure powder addition compartment, a removable drawer for recycling excess powder, and an automatic collection system that optimizes film handling and reduces production errors.

No, the SM3's design is intuitive and easy to use, allowing anyone to operate it with minimal training. Its digital control simplifies the necessary adjustments to achieve perfect results in every job.

The integrated smoke purifier removes harmful gases and particles from the curing process, creating a safer and cleaner work environment. The HEPA and carbon filters ensure effective contaminant removal and are easily replaceable when saturated.

An automatic dryer and shaker like the InkOne SM3 significantly improves efficiency by combining powder application and curing into a single machine, reducing production time and waste while optimizing workflow. The InkOne SM3 is highly versatile and can handle both large and small productions, thanks to its continuous production capacity and digital control that allows precise adjustments according to the needs of each project.

Contact us

UDesign Address

8500 Bevery boulevard Los Angeles, New York, CA 90048

Business Hours

We are open 6 days a week from 7am to 9pm, Sunday closed

Let's Talk

Phone Number: (0) 123-456-7890

Fax: +000 123-456-789