Total Automation

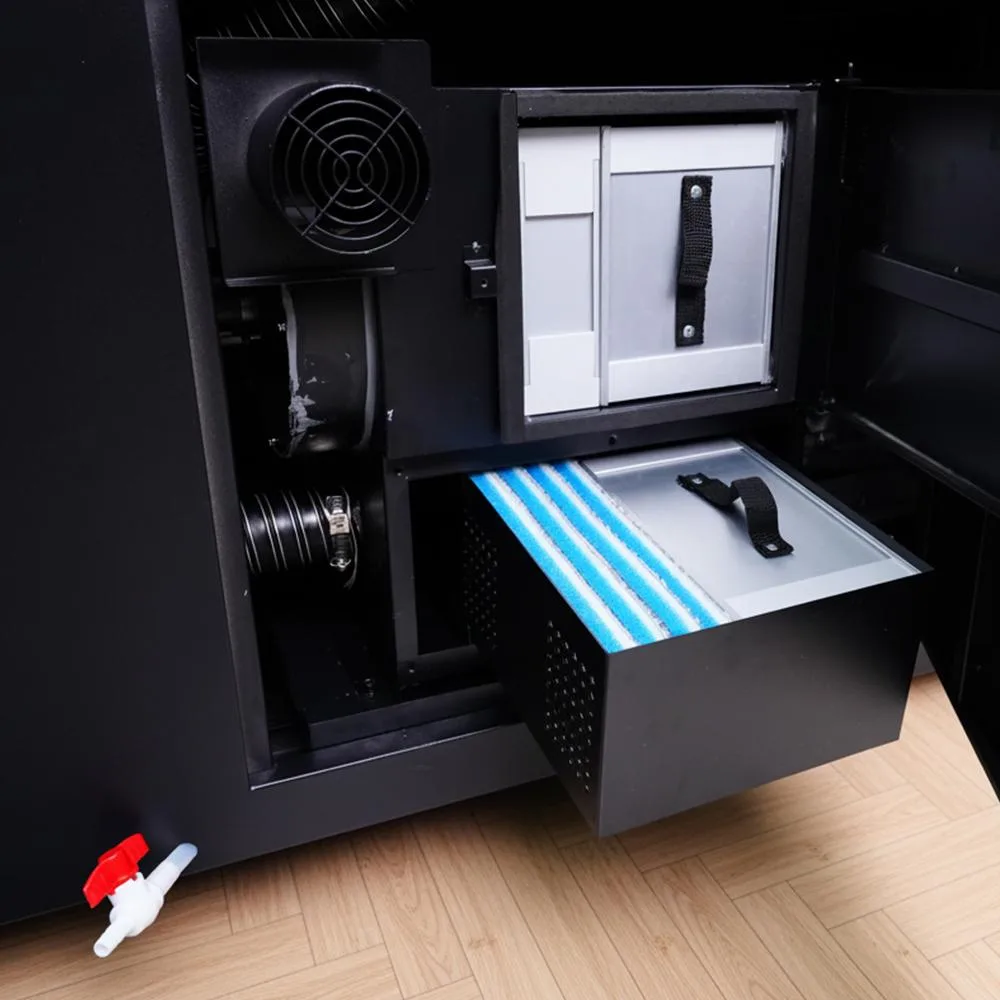

The DTF Dryer and Shaker InkOne SX8 (60 cm) combines powder application and thermal curing in a single machine, optimizing time and enhancing print quality.

Precise Digital Control

Easily adjust temperature, powder application speed, agitation, preheating, and more — ensuring flawless curing across all types of DTF films, inks, and powders.

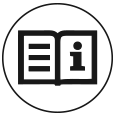

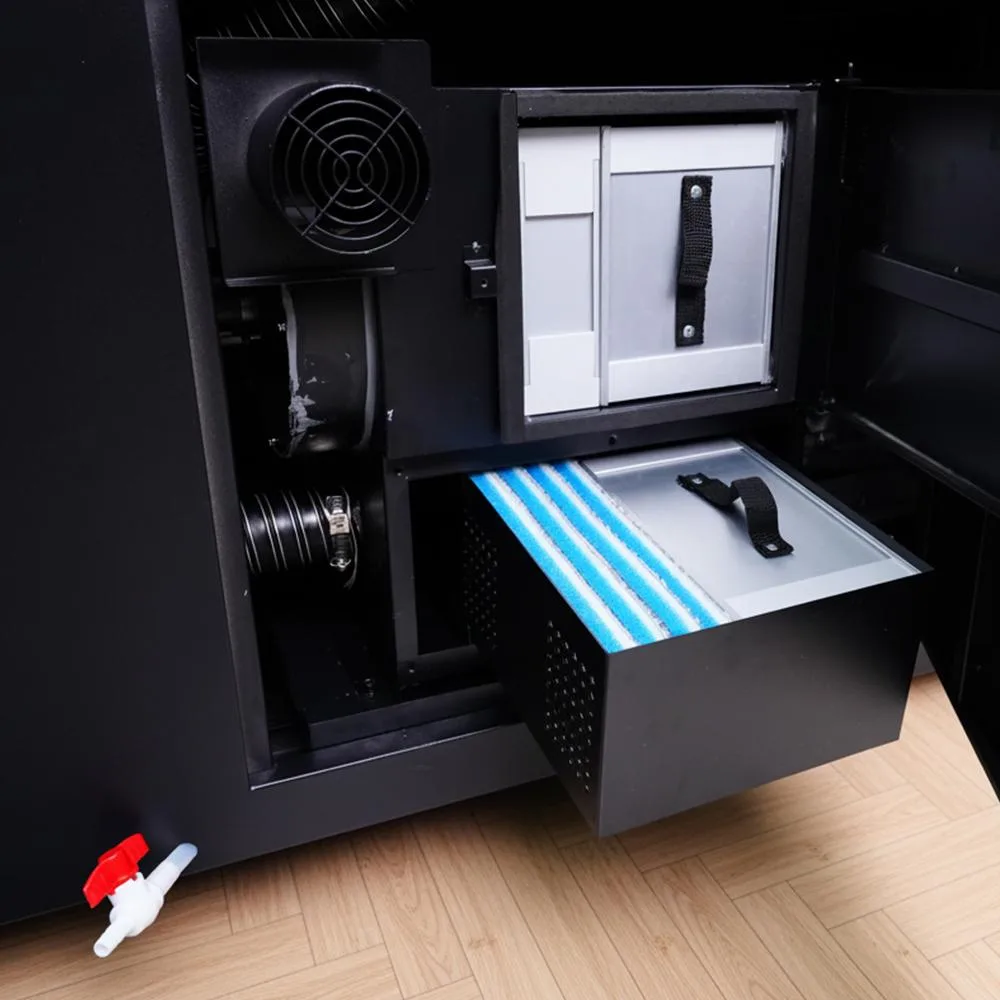

Integrated Purifier

Includes a purification system with HEPA and activated carbon filters, ensuring a cleaner and safer work environment by eliminating fumes and airborne particles from the process.

DTF Dryer and Shaker InkOne SX8

The DTF Dryer and Shaker InkOne SX8 (60 cm) is a state-of-the-art machine that combines efficiency, safety, and quality in the production of DTF transfers. Designed to work with printers up to 60 cm wide, this system automates polyamide powder application and film curing, reducing errors and boosting productivity.

- The InkOne SX8 supports films up to 60 cm wide, making it ideal for large-format production.

- The automated powder applicator dispenses and agitates with precision, ensuring consistent coating on every job.

- The multifunctional digital panel offers centralized control of oven temperature, speed, and ventilation.

- The front preheating system removes moisture from the film before curing, preventing defects in the print.

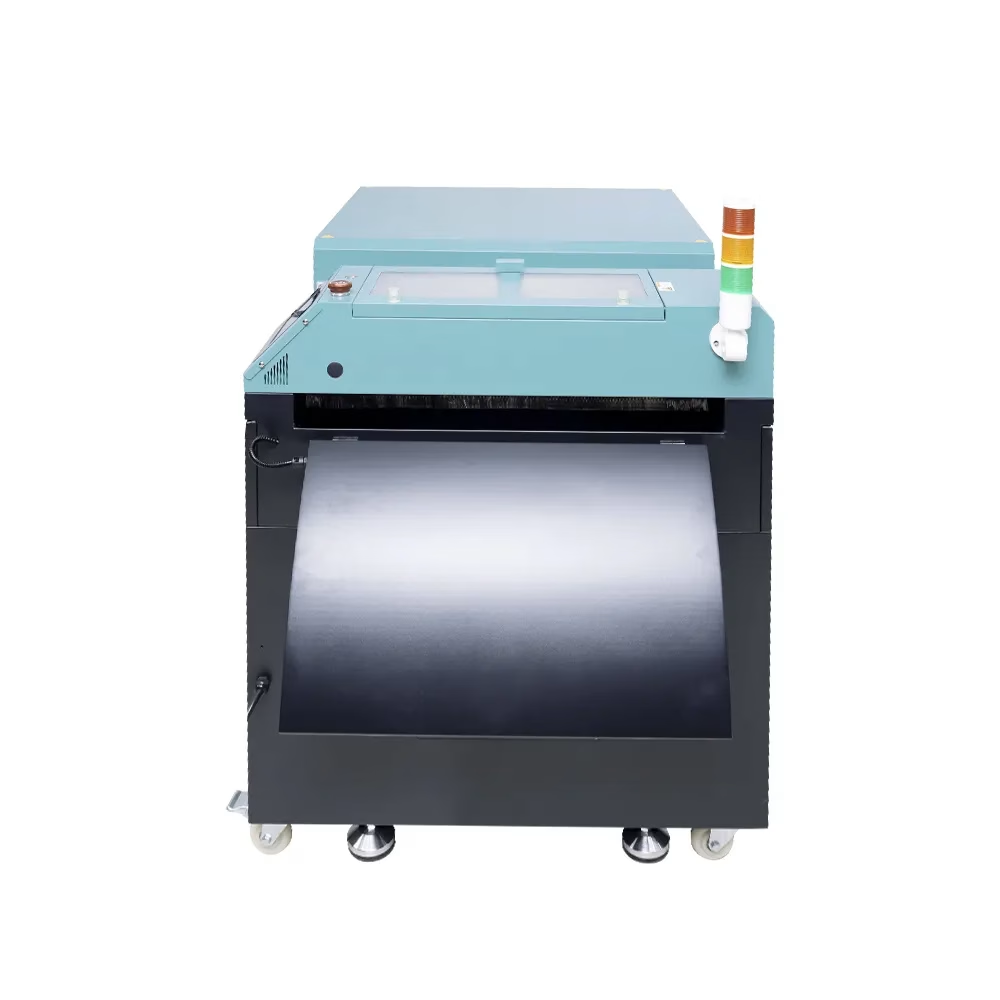

- The air-suction conveyor belt keeps the film steady during the drying process, ensuring perfect alignment.

- The quick-access top powder hopper makes refilling easy without interrupting production flow.

- The removable drawer allows you to collect and reuse excess powder, keeping the equipment clean and minimizing waste.

- HEPA and activated carbon filters purify the air, ensuring a safe, fume-free working environment.

Technical Specifications | DTF Dryer and Shaker InkOne SX8 |

|---|---|

Maximum paper/film width | 60 cm |

Powder filling box | Yes |

Powder collection drawer | Yes |

Supported speed | 15m2/h |

Parameter control | Digital control panel (temperature, speed, agitation, preheating, etc.) |

Smoke extractor control | Digital panel |

Voltage | 220V |

Equipment dimensions | 188,4 x 91,2 x 99,0 cm |

Packaging dimensions | 160,0 x 113,0 x 111,3 cm |

Oven weight | 192 Kg |

INTRODUCTION

InkOne SX8

Dryer Oven VS Dryer and Shaker

Feature | Dryer Oven | Dryer and Shaker |

|---|---|---|

Main function | Image curing | Powder application, excess powder removal, image curing, and film storage |

Powder application | Manual | Automatic |

Film or paper format | Sheets | Rolls |

Powder recycling | Not available | Recycling system |

Process time | Variable, depends on operator | Film passes continuously from start to finish |

Production speed | Variable, depends on operator | Constant, automatically adjustable |

Operator safety | Operator handles hot objects | Operator does not handle hot objects |

Film/paper handling | Manual | Automatic collection system |

Continuous production capacity | Limited | High, for large volumes |

Frequently Asked Questions

The SX8 stands out for its full automation, multifunctional digital panel, integrated smoke purification system with HEPA and activated carbon filters, and its ability to produce highly precise DTF transfers on films up to 60 cm wide.

No, the machine is designed so that anyone can operate it with minimal training. Its intuitive digital interface simplifies control and ensures an accessible user experience.

The InkOne SX8 includes an integrated purification system with HEPA and activated carbon filters to maintain a clean and safe environment during production. It also features a front preheating system to avoid film defects, a low-powder warning to maintain workflow, excess powder recycling, and a smart safety mode that stops the machine if opened accidentally.

An automatic machine like the InkOne SX8 greatly improves efficiency by combining powder application and curing into a single system. This reduces production time and waste while streamlining the workflow. The SX8 is ideal for customization workshops, textile companies, and print businesses that need to produce high-volume DTF transfers with precision, quality, and safety.

Contact us

UDesign Address

8500 Bevery boulevard Los Angeles, New York, CA 90048

Business Hours

We are open 6 days a week from 7am to 9pm, Sunday closed

Let's Talk

Phone Number: (0) 123-456-7890

Fax: +000 123-456-789