Specialized Design

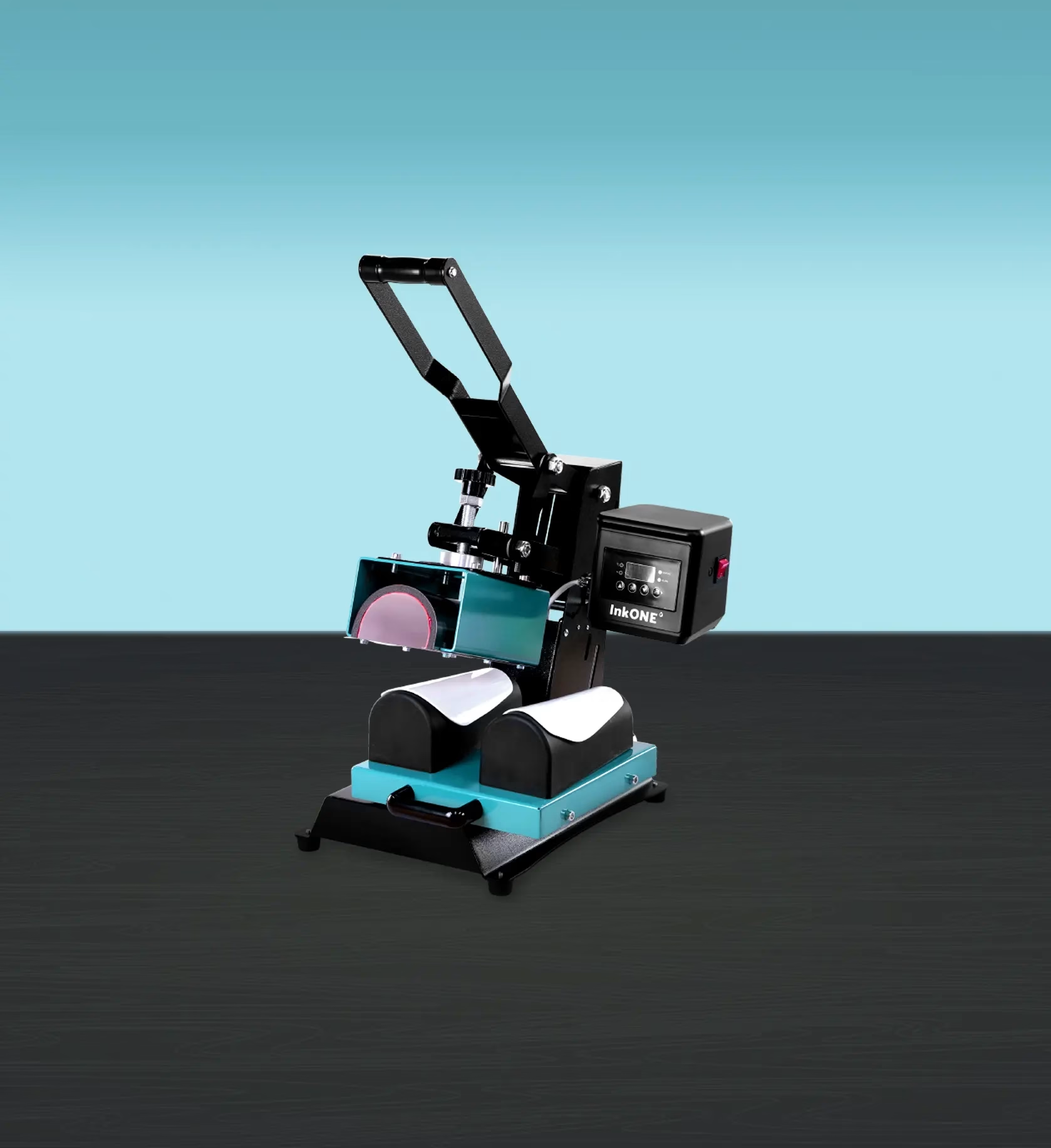

The Heat Press InkOne S1 for shin guards is a professional heat press specifically designed to customize sports shin guards through sublimation, with precision, safety, and efficiency.

Maximum Productivity

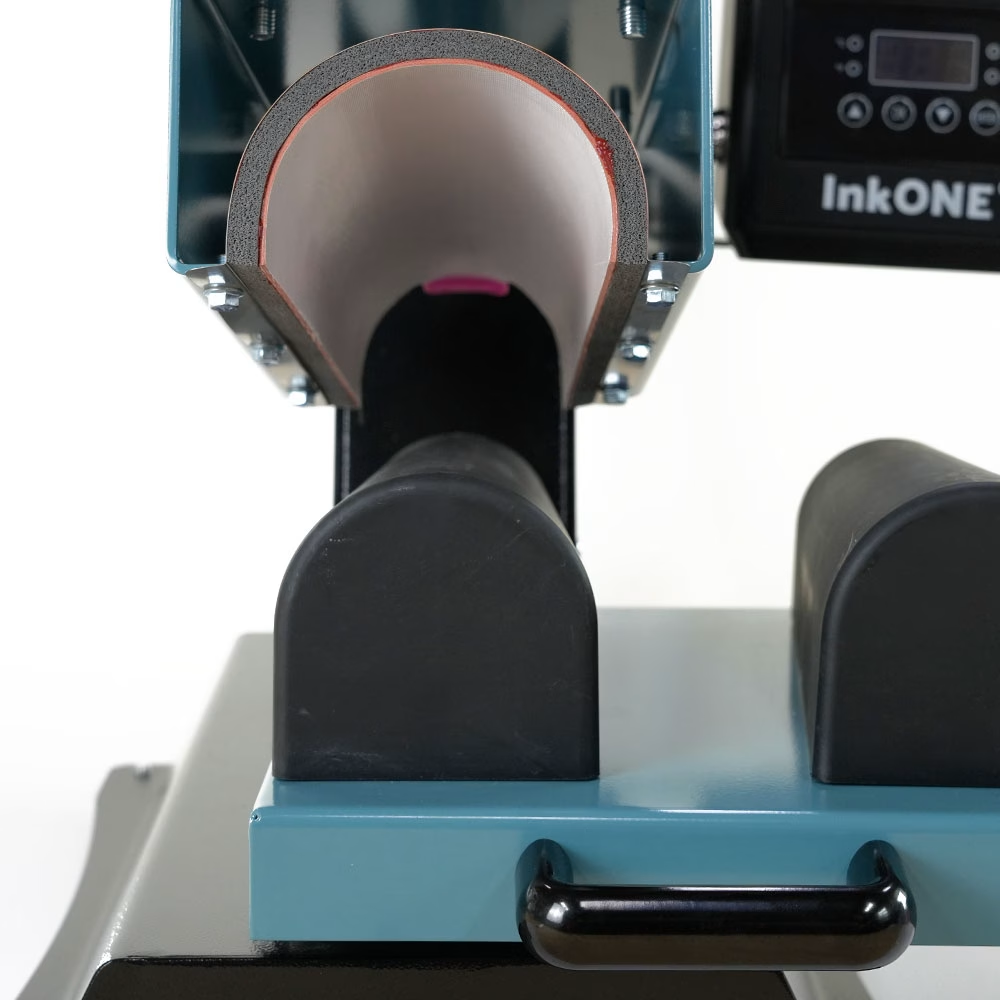

Allows you to sublimate two shin guards alternately thanks to its dual mold system with lateral displacement.

Precision and safety

Its panel with temperature and time adjustment, force-multiplying arm, and silicone base ensure excellent results in every pressing cycle.

Heat Press InkOne S1 for shin guards

The Heat Press InkOne S1 for shin guards is a professional press specially designed for customizing sports shin guards using the sublimation technique. Ideal for textile workshops, sports stores or entrepreneurs looking for an efficient and reliable shin guard heat press capable of delivering high-quality results with every use.

- Heat press for shin guards with double lower mold and lateral displacement.

- Allows alternating between two pressing zones to optimize production.

- Digital control panel with precise temperature and time adjustment.

- Automatic opening via gas spring system, ideal for continuous work.

- Base with silicone pad to protect the material and ensure a perfect finish.

- Manual pressure regulator (wheel type) for quick adjustments depending on shin guard thickness.

Technical Specifications | Heat Press InkOne S1 for shin guards |

|---|---|

Press type | For shin guards |

Lower base | Dual mold with lateral sliding |

Opening | Automatic with pneumatic springs |

Opening type | Sandwich |

Digital time and temperature panel | GY-06 controller |

Pressure adjustment | Manual |

Voltage | 120 / 220 V |

Time range | 0 - 999 seconds |

INTRODUCTION

InkOne S1 for shin guards

Advantages of the Heat Press InkOne S1 for shin guards

Shin guard heat press | InkOne S1 |

|---|---|

Specialized design | Developed by customization experts, exclusively for sublimating shin guards with precision |

Consistent quality | Digital control and even pressure ensure professional results with every use |

Increased productivity | The dual-mold system allows alternating pressing of two shin guards without pauses |

High reliability | Robust structure, automatic system, and durable components that withstand daily work |

Tailored support | We support decorators with technical solutions, expert advice, and useful content |

Professional brand | Choosing InkOne means investing in high-performance technology for sports customization |

Frequently Asked Questions

The InkOne S1 is a heat press specifically designed for the customisation of shin guards. Its main function is to apply heat and pressure evenly to areas where a flat heat press cannot achieve proper contact. It is intended for heat transfer applications such as sublimation on prepared shin guards and other systems compatible with this type of curved surface.

The InkOne S1 allows customisation of shin guards made from materials suitable for heat transfer, such as specific polymers and coated surfaces designed for sublimation. It is essential that the material can withstand both heat and pressure without deforming. The InkOne S1 adapts to the shape of the product, reducing errors and improving the final finish.

Although optimised for shin guards, the InkOne S1 can also be used for other small products with a similar curved shape, provided they fit correctly on the pressing base. It does not replace a flat or multifunction heat press, but it is a specialised solution for businesses that regularly work with this type of product.

Customising shin guards is a high value-added niche, especially in sports and promotional markets. Investing in an InkOne S1 is generally affordable and can be recovered quickly when working with personalised orders or sports teams. As a specialised machine, it improves efficiency and reduces waste compared to improvised solutions.

The InkOne S1 is aimed at entrepreneurs and professionals who want to offer customised shin guards as a core or complementary product. It is ideal for customisation workshops, sports retailers and businesses working with personalised orders, where consistency and quality are essential.

Contact us

UDesign Address

8500 Bevery boulevard Los Angeles, New York, CA 90048

Business Hours

We are open 6 days a week from 7am to 9pm, Sunday closed

Let's Talk

Phone Number: (0) 123-456-7890

Fax: +000 123-456-789