Compact and professional

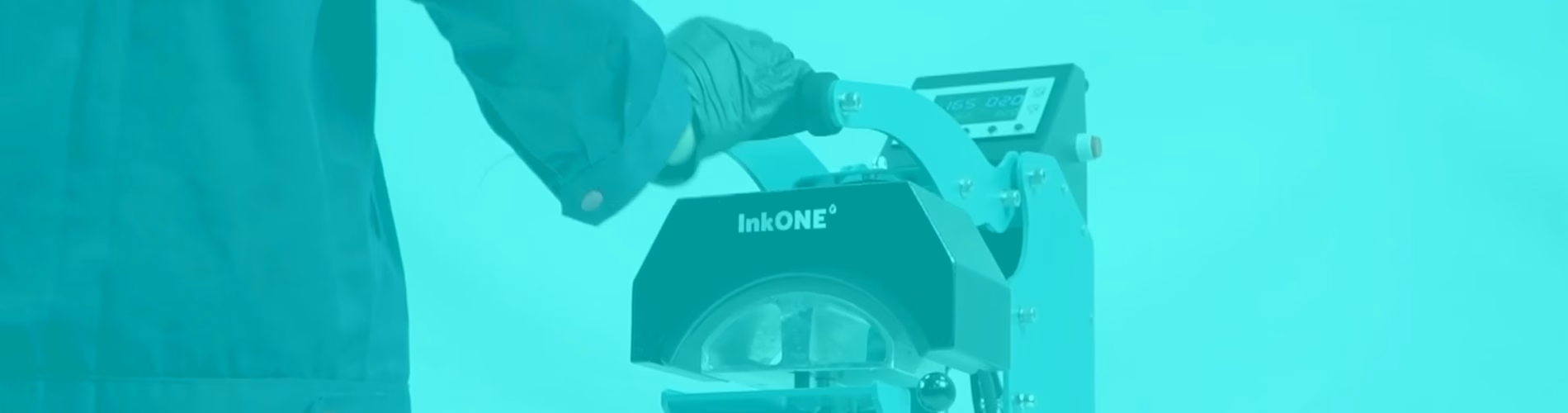

The InkOne C1 Heat Press for caps is a 2-in-1 cap press designed to personalize caps and small-format textiles with great precision.

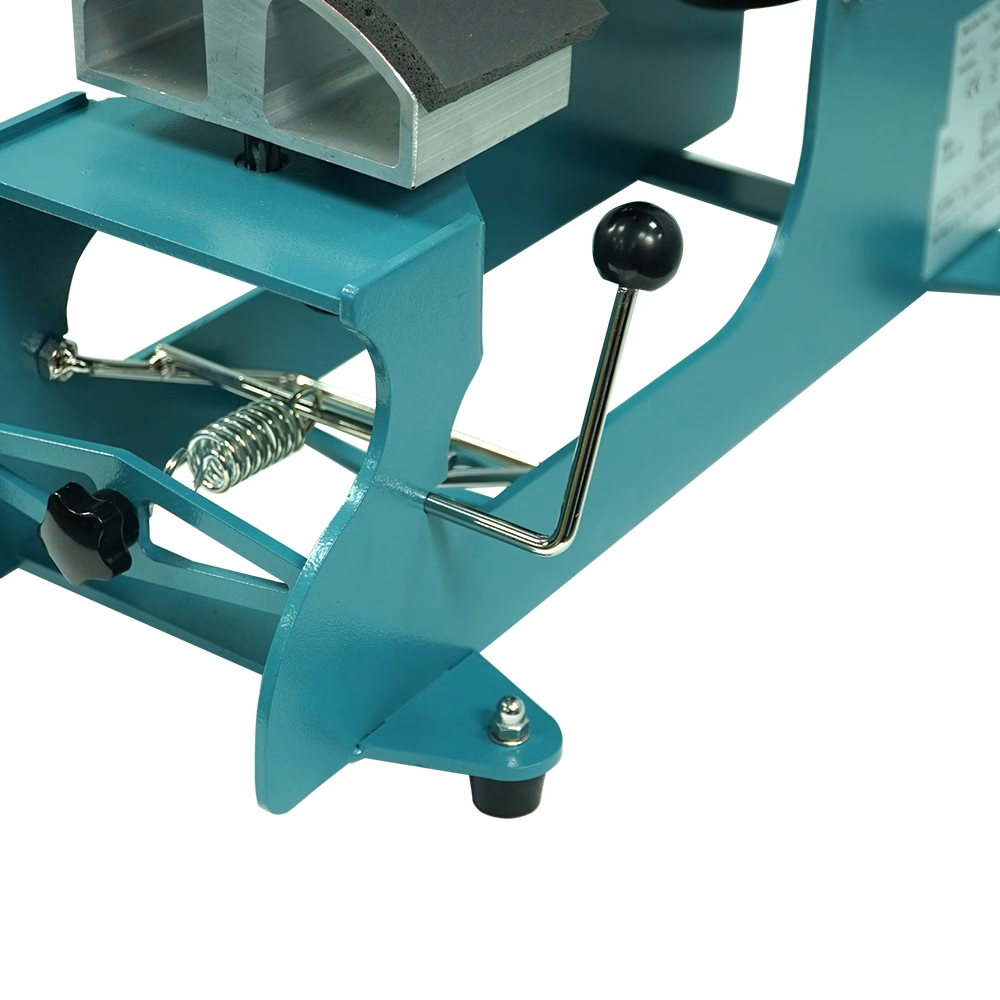

Interchangeable plates*

Includes a 7.5 x 16 cm plate for caps and a 15×15 cm plate for small-format textile or rigid products

Easy to use

Its intuitive digital panel, automatic opening, and pressure system make cap pressing comfortable, fast, and deliver professional results on every product

InkOne C1 Heat Press for caps

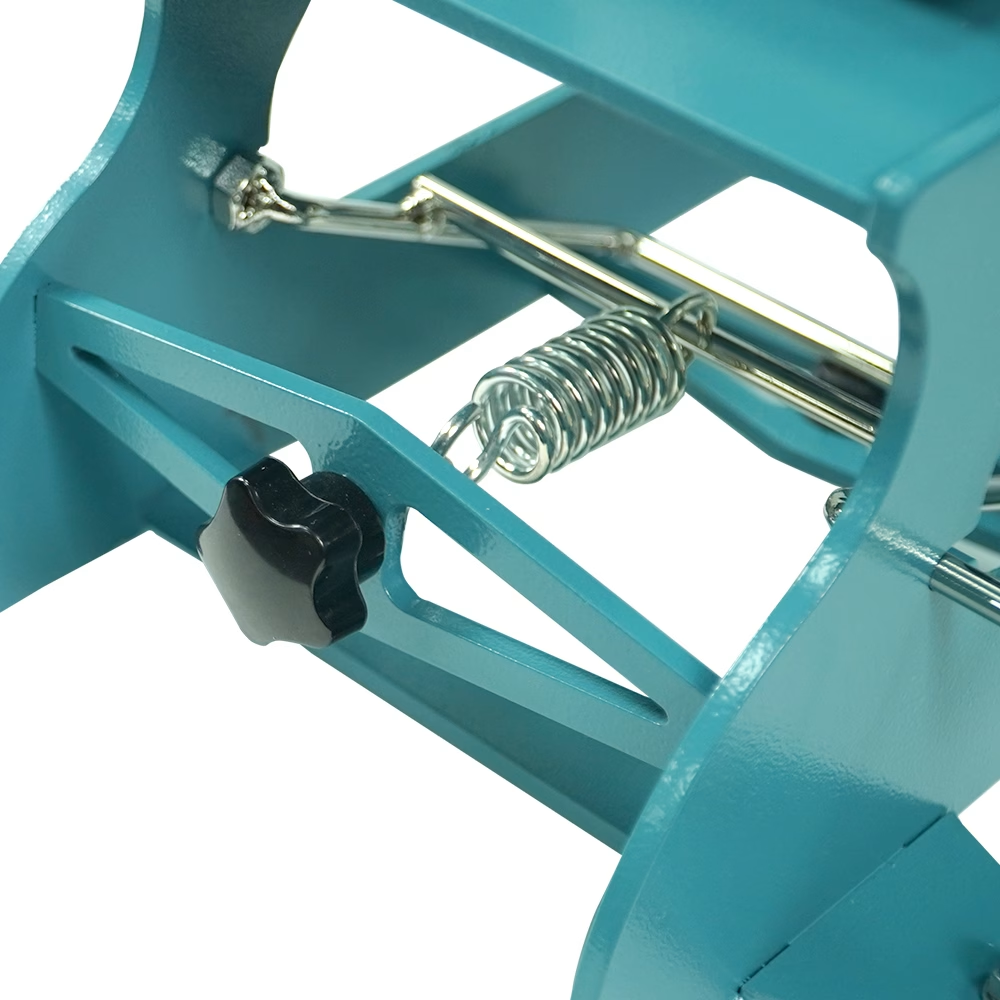

- Automatic opening with gas springs.

- Compact design, ideal for small spaces.

- Precise control of temperature (up to 225 °C) and time (up to 999 s).

- Uniform pressure thanks to the integrated force multiplier arm.

- Cap plate of 7.5 x 16 cm

- Flat plate of 15 x 15 cm for small-format textiles and rigid products

- Adjustable pressure manually via wheel

Technical Specifications | InkOne C1 Heat Press for caps |

|---|---|

Type of press | For caps and small-format textiles or rigid items |

Cap plate size | 7.5 x 16 cm |

Flat plate size | 15 x 15 cm |

Opening | Automatic with pneumatic springs |

Opening type | Sandwich |

Digital time and temperature panel | GY-06 controller |

Interchangeable plates (Not included) | 7.2 x 18 cm 10 x 17.5 cm 10 x 23 cm |

Pressure adjustment | Manual |

Voltage | 120 / 220 V |

Power (KW) | 500-1000 W |

Time range | 0 - 999 seconds |

Maximum temperature | 225 ºC |

INTRODUCTION

InkOne C1 for caps

Frequently Asked Questions

The InkOne C1 is a heat press specifically designed for customising caps and curved-surface products. Its structure allows heat and pressure to be applied evenly across the front panel of the cap, something that cannot be achieved with a standard flat heat press. It is mainly intended for heat transfer techniques such as sublimation on prepared caps, DTF and other systems compatible with curved surfaces.

With the InkOne C1 cap press, it is possible to personalise most common cap types on the market, provided they are suitable for heat transfer. This includes cotton, polyester and blended caps, as well as structured and semi-structured models. The key requirement is that the material can withstand the working temperature and that the cap has a suitable front panel for pressing.

Although it is optimised for caps, the InkOne C1 can also be used for other small items with a curved surface and similar shape, as long as they fit correctly on the pressing base. It does not replace a flat or multifunction heat press, but it is a specialised solution that delivers better results when cap customisation is the main focus.

The interchangeable platens for the InkOne C1 are designed to adapt to different cap shapes and styles. They allow the working surface to be adjusted to the exact form of the product, improving heat and pressure distribution during the transfer process. Thanks to these dedicated platens, it is possible to work more accurately with caps of different sizes, structures and profiles, achieving more uniform and professional finishes than with a standard platen.

The main difference lies in adaptation to the curved shape of the cap. A flat heat press cannot apply even pressure on curved surfaces, which can result in poor adhesion or wrinkles. The InkOne C1 is specifically designed to match the shape of the cap, improving finish quality and reducing errors, especially in repeated production runs.

Using original InkOne interchangeable platens with the C1 provides clear advantages in terms of quality and versatility. Being able to adapt the platen to the type of cap reduces the risk of wrinkles, uneven transfers or inconsistent pressure. These accessories are specifically engineered to work seamlessly with the InkOne C1, ensuring stability, safety and consistent results. For workshops that personalise different cap models or work on demand, interchangeable platens allow the product range to expand without changing equipment.

Yes, the InkOne C1 is designed to be easy to use even for beginners entering the customisation market. Temperature and time controls are intuitive, and the machine design helps position the cap correctly from the first use. This shortens the learning curve and allows users to start producing with fewer errors compared to non-specialised solutions.

Contact us

UDesign Address

8500 Bevery boulevard Los Angeles, New York, CA 90048

Business Hours

We are open 6 days a week from 7am to 9pm, Sunday closed

Let's Talk

Phone Number: (0) 123-456-7890

Fax: +000 123-456-789