UV-DTF Printing

High quality and versatility for rigid surface customization

UV-DTF printing is a revolutionary technique that allows high-quality designs to be transferred onto a wide range of rigid surfaces such as glass, metal, wood, ceramic, and plastic. It uses UV-DTF printers to print designs onto a special film (Film A), which is then transferred via lamination onto a carrier film (Film B). Once ready, the stickers can be applied manually using only your hands. UV-DTF technology stands out for its instant curing, vibrant colours, and exceptional durability.

Main advantages of UV-DTF printing

- Maximum versatility: applicable to a wide variety of surfaces, including both rigid and flexible materials.

- High image quality: uses UV inks that cure instantly under ultraviolet light, delivering vivid colours and precise detail.

- Clean and efficient process: images are applied manually without the need for complex pretreatment steps.

- Durability: long-lasting results resistant to wear, scratches, UV rays, and chemicals.

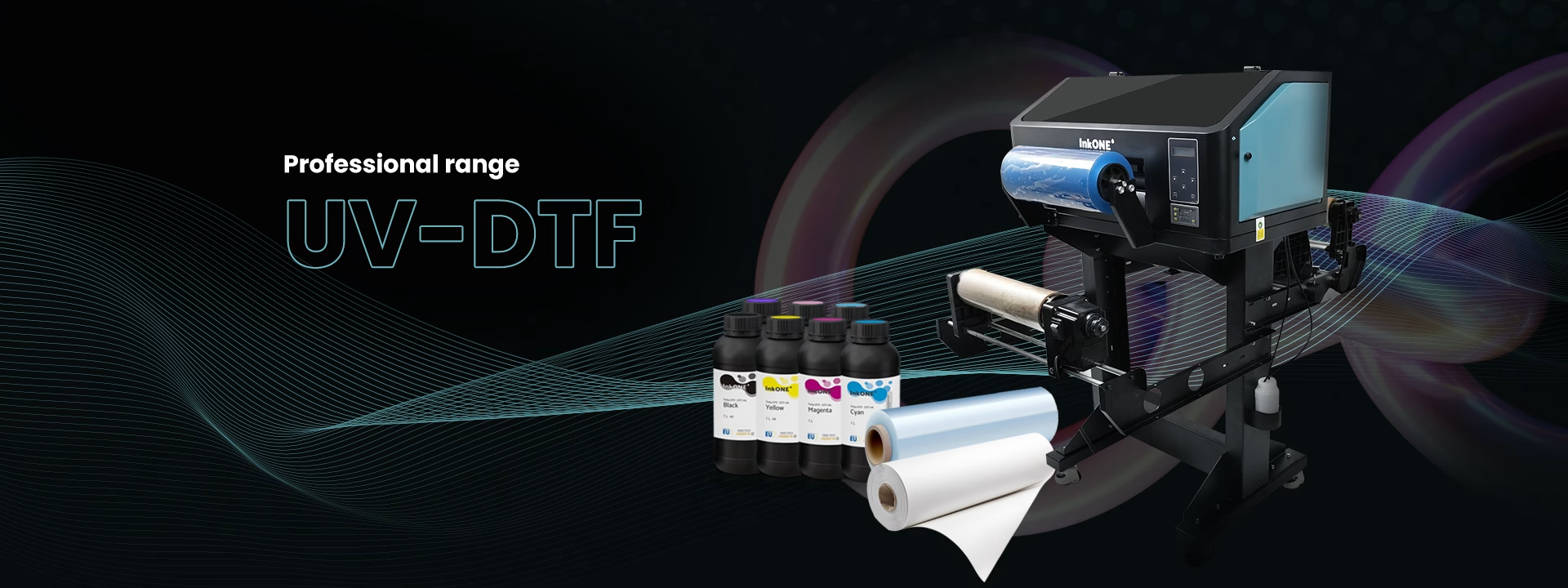

Why choose an InkOne UV-DTF printer?

InkOne has positioned itself as a leading brand in UV-DTF technology, offering complete solutions focused on quality and customer satisfaction. From printers to consumables and spare parts, each product in our catalogue has been developed by experts to ensure top-tier performance and optimized efficiency.

InkOne UV-DTF printers are known for their speed and ability to reproduce fine details, making them the ideal tool for demanding applications. Our InkOne DTF Films A and B ensure optimal adhesion and flawless transfer on a wide range of surfaces. InkOne UV inks, formulated to deliver vibrant colours and outstanding resistance, ensure professional-grade finishes. Additionally, brand-specific accessories and spare parts help maintain consistent performance, protect your investment, and ensure long-term reliability.

Beyond our full range of equipment and consumables for UV-DTF printing, InkOne also offers:

- Products with warranty and certified quality

- Technical support and assistance: we provide specialized technical service and expert advice for troubleshooting and repairs, ensuring you always have the support you need.

- Spare parts available: we stock replacement parts for all our machines, making quick repairs easy and helping maintain your equipment’s peak performance.

- Visual and remote support: through our YouTube channel, we offer support, maintenance, and repair videos. When needed, we can also provide remote assistance to quickly and efficiently resolve any issues.

InkOne UV-DTF Printers

UV printing and lamination technology for professional-grade customization on all types of surfaces.

InkOne UV-DTF printers, such as the InkOne UM3, integrate the entire printing and lamination process into a single machine: UV printing on Film A and lamination onto Film B. They are equipped with advanced operation and maintenance systems to ensure a precise, convenient, and professional workflow.

InkOne UV-DTF Accessories and Consumables

Everything you need to achieve consistent results, vibrant prints, and long-lasting performance.

Complete your UV-DTF workflow with InkOne’s range of accessories and consumables, carefully selected to ensure professional quality. From high-adhesion Films A and B, next-generation UV inks, daily maintenance cleaners, to finishing varnishes—each product is designed to maximize your printer’s performance and the durability of your applications.

UV-DTF Spare Parts

We offer a complete range of high-quality replacement parts.

InkOne UV-DTF spare parts are designed to extend the lifespan of your equipment and maintain optimal performance without interruptions. From printheads compatible with UV inks to filters, tanks, cappings, encoders, and tubes—each component ensures quick installation and maximum compatibility. With original InkOne parts, you guarantee easy maintenance and consistent results with every print.

Frequent questions

UV DTF printing is a customisation technique that allows printed adhesive transfers to be created using UV inks and then applied to a wide variety of surfaces without the need for heat. InkOne relies on this technology because it combines versatility, high quality and ease of use, offering an efficient solution for both entrepreneurs and professionals looking to expand their production capabilities without complex processes or material limitations.

UV DTF printing makes it possible to personalise materials such as plastic, glass, metal, treated wood, ceramic, acrylic and lacquered surfaces. Since the design is not printed directly onto the final object, many of the usual limitations of other techniques are eliminated. This makes InkOne UV DTF technology particularly suitable for promotional items, customised products and objects with irregular shapes.

Maintenance of InkOne UV DTF equipment is straightforward and focused on supporting daily operation. It includes basic tasks such as printhead cleaning, monitoring UV inks and proper handling of consumables. Because white ink contains heavier pigments, regular daily, weekly and monthly maintenance is recommended to ensure long equipment lifespan and consistent print quality.

InkOne does not simply sell printers; it provides a complete solution that includes machines, consumables, accessories and spare parts for each system. This offers greater reliability, reduces compatibility issues and supports business scalability. In addition, InkOne provides continuous technical support, both on-site and online, as well as audiovisual training resources.